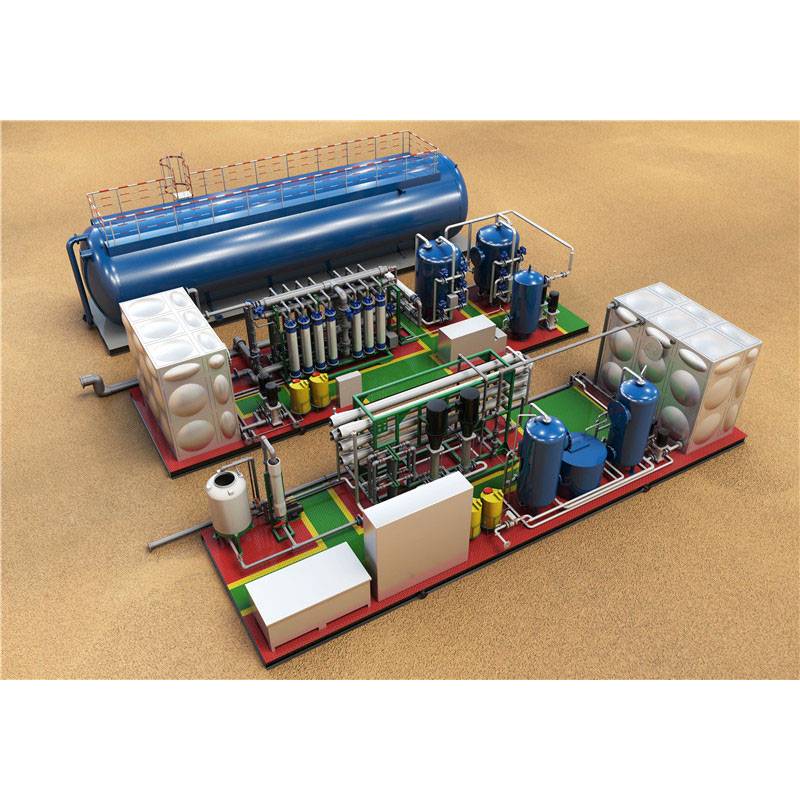

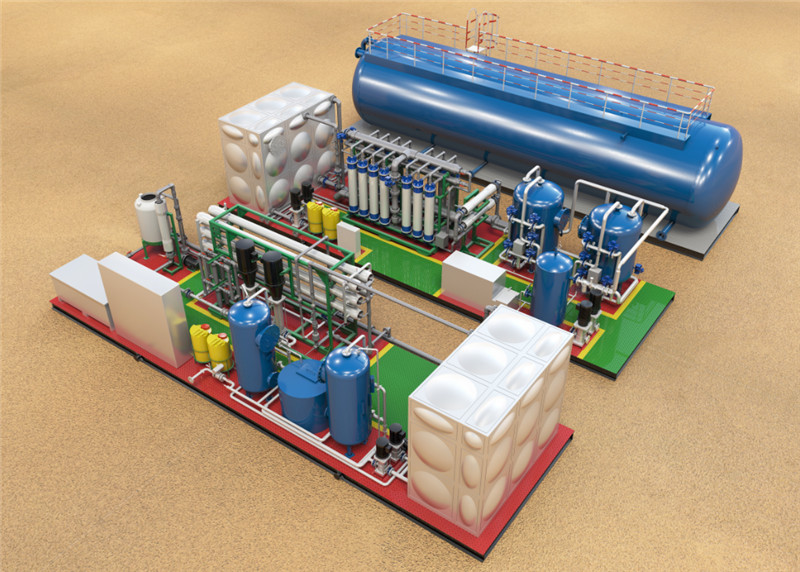

China Seawater Desalination RO +EDI system for steam boiler

With a positive and progressive attitude to customer’s interest, our company continuously improves our product quality to meet the needs of customers and further focuses on safety, reliability, environmental requirements, and innovation of China Seawater Desalination RO +EDI system for steam boiler, In addition, we would properly guide the customers about the application techniques to adopt our products and the way to select appropriate materials.

With a positive and progressive attitude to customer’s interest, our company continuously improves our product quality to meet the needs of customers and further focuses on safety, reliability, environmental requirements, and innovation of , To win customers’ confidence, Best Source has set up a strong sales and after-sales team to offer the best product and service. Best Source abides by the idea of “Grow with customer” and philosophy of “Customer-oriented” to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let’s grow together!

Explanation

Climate change and the rapid development of global industry and agriculture have made the problem of lack of fresh water increasingly serious, and the supply of fresh water is becoming increasingly tense, so some coastal cities are also seriously short of water. The water crisis poses an unprecedented demand for seawater desalination machine for producing fresh drinking water. Membrane desalination equipment is a process in which seawater enters through a semi-permeable spiral membrane under pressure, the excess salt and minerals in the seawater are blocked on the high pressure side and are drained out with concentrated seawater, and the fresh water is coming out from the low pressure side.

Process Flow

Seawater → Lifting pump → Flocculant sediment tank → Raw water booster pump → Quartz sand filter → Activated carbon filter → Security filter → Precision filter → High pressure pump → RO system → EDI system → Production water tank → water distribution pump

Components

● RO membrane: DOW, Hydraunautics, GE

● Vessel: ROPV or First Line, FRP material

● HP pump: Danfoss super duplex steel

● Energy recovery unit: Danfoss super duplex steel or ERI

● Frame: carbon steel with epoxy primer paint, middle layer paint, and polyurethane surface finishing paint 250μm

● Pipe: Duplex steel pipe or stainless steel pipe and high pressure rubber pipe for high pressure side, UPVC pipe for low pressure side.

● Electrical: PLC of Siemens or ABB , electrical elements from Schneider.

Application

● Marine engineering

● Power plant

● Oil field, petrochemical

● Processing enterprises

● Public energy units

● Industry

● Municipal city drinking water plant

Reference Parameters

|

Model |

Production water (t/d) |

Working Pressure (MPa) |

Inlet water temperature(℃) |

Recovery rate (%) |

Dimension (L×W×H(mm)) |

|

JTSWRO-10 |

10 |

4-6 |

5-45 |

30 |

1900×550×1900 |

|

JTSWRO-25 |

25 |

4-6 |

5-45 |

40 |

2000×750×1900 |

|

JTSWRO-50 |

50 |

4-6 |

5-45 |

40 |

3250×900×2100 |

|

JTSWRO-100 |

100 |

4-6 |

5-45 |

40 |

5000×1500×2200 |

|

JTSWRO-120 |

120 |

4-6 |

5-45 |

40 |

6000×1650×2200 |

|

JTSWRO-250 |

250 |

4-6 |

5-45 |

40 |

9500×1650×2700 |

|

JTSWRO-300 |

300 |

4-6 |

5-45 |

40 |

10000×1700×2700 |

|

JTSWRO-500 |

500 |

4-6 |

5-45 |

40 |

14000×1800×3000 |

|

JTSWRO-600 |

600 |

4-6 |

5-45 |

40 |

14000×2000×3500 |

|

JTSWRO-1000 |

1000 |

4-6 |

5-45 |

40 |

17000×2500×3500 |

Project Case

Seawater Desalination machine

720tons/day for offshore oil refinery plant

Container Type Seawater Desalination machine

500tons/day for Drill Rig Platform

Seawater desalination is indeed a common method to obtain high-purity water for steam boilers. Following are the steps involved in the desalination process: Pretreatment: Seawater usually contains suspended solids, organic matter and algae, which need to be removed before desalination. Pretreatment steps may include filtration, flocculation and coagulation processes to remove these impurities. Reverse Osmosis (RO): The most common desalination method is reverse osmosis. During this process, seawater is passed under pressure through a semipermeable membrane that allows only pure water molecules to pass through, leaving dissolved salts and other impurities behind. The resulting product is called permeate. Post-treatment: After reverse osmosis, the permeate may still contain some impurities.

Seawater desalination is indeed a common method to obtain high-purity water for steam boilers. Following are the steps involved in the desalination process: Pretreatment: Seawater usually contains suspended solids, organic matter and algae, which need to be removed before desalination. Pretreatment steps may include filtration, flocculation and coagulation processes to remove these impurities. Reverse Osmosis (RO): The most common desalination method is reverse osmosis. During this process, seawater is passed under pressure through a semipermeable membrane that allows only pure water molecules to pass through, leaving dissolved salts and other impurities behind. The resulting product is called permeate. Post-treatment: After reverse osmosis, the permeate may still contain some impurities.

Combining reverse osmosis (RO) with electrodeionization (EDI) is a common method of desalination to obtain high purity water for steam boilers.

Electrodeionization (EDI): The RO permeate is then further purified by EDI. EDI uses an electric field and an ion-selective membrane to remove any residual ions from the RO permeate. This is an ion exchange process in which positively and negatively charged ions are attracted to opposite poles and removed from the water. This helps achieve higher levels of purity. Post-treatment: After the EDI process, the water may undergo additional post-treatment to ensure its quality meets the requirements for steam boiler feed water.

Treated water is stored in tanks and distributed to steam boilers. It is very important to ensure proper storage and distribution systems to prevent any contamination of high purity water. Regular monitoring of water quality parameters such as conductivity, pH, dissolved oxygen and total dissolved solids is critical to maintaining the high levels of purity required for steam boiler operation. The combination of RO and EDI provides an efficient and reliable method for producing high purity water from seawater for use in steam boilers. However, factors such as energy consumption, maintenance and operating costs must be considered when implementing a desalination system using RO and EDI technologies.