Good Quality Sodium Hypochlorite Generator - 8tons Sodium Hypochlorite Generator – Jietong Water Treatment

Good Quality Sodium Hypochlorite Generator - 8tons Sodium Hypochlorite Generator – Jietong Water Treatment Detail:

Explanation

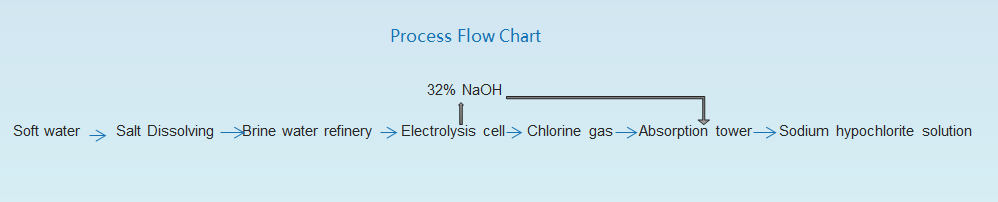

Membrane electrolysis sodium hypochlorite generator is a suitable machine for drinking water disinfection, wastewater treatment, sanitation and epidemic prevention, and industrial production, which is developed by Yantai Jietong Water Treatment Technology Co., Ltd., China Water Resources and Hydropower Research Institute, Qingdao University, Yantai University and other research institutes and universities. Membrane sodium hypochlorite generator designed and manufactured by Yantai Jietong Water Treatment Technology Co., Ltd. can produce 5-12% high concentration sodium hypochlorite solution with a closed loop of producing fully automated operation.

Quick Details

Place of Origin:China Brand Name:JIETONG

Warranty:1 Year

Capacity: 8ton/day sodium hypochlorite generator

Characteristic: customerized Production time: 90days

Certificate:ISO9001, ISO14001, OHSAS18001

Technical Data:

Capacity: 8tons/day

Concentration: 10-12%

Raw material: High Purity Salt and City tap water

Salt consumption: 1700kg/day

Power consumption: 140kw.h

Working Principle

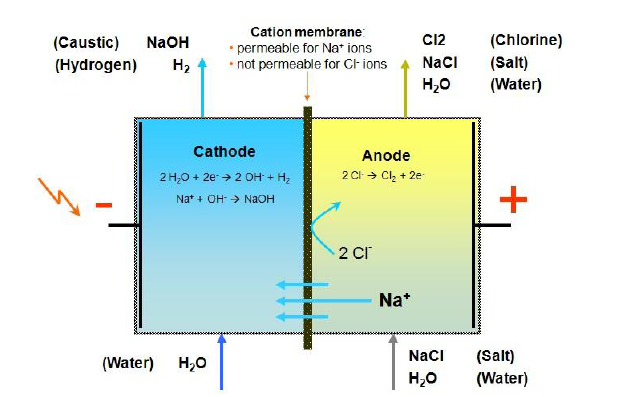

The basic principle of electrolytic reaction of membrane electrolysis cell is to convert electric energy into chemical energy and electrolyze brine to produce NaOH, Cl2 and H2 as shown in the above picture. In the anode chamber of the cell (on the right side of the picture), the brine is ionized into Na+ and Cl- in the cell, wherein Na+ migrates to the cathode chamber (left side of the picture) through a selective ionic membrane under the action of charge. The lower Cl- generates chlorine gas under anodic electrolysis. The H2O ionization in the cathode chamber becomes H+ and OH-, wherein OH- is blocked by a selective cation membrane in the cathode chamber and Na+ from the anode chamber is combined to form product NaOH, and H+ generates hydrogen under cathodic electrolysis.

Application

● Chlorine-alkali industry

● Disinfection for water plant

● Bleaching for clothes making plant

● Diluting to low concentration active chlorine for home, hotel, hospital.

Reference Parameters

|

Model

|

Chlorine (kg/h) |

NaClO (kg/h) |

Salt consumption (kg/h) |

DC Power consumption (kW.h) |

Occupy area (㎡) |

Weight (tons) |

| JTWL-C1000 |

1 |

10 |

1.8 |

2.3 |

5 |

0.8 |

| JTWL-C5000 |

5 |

50 |

9 |

11.5 |

100 |

5 |

| JTWL-C10000 |

10 |

100 |

18 |

23 |

200 |

8 |

| JTWL-C15000 |

15 |

150 |

27 |

34.5 |

200 |

10 |

| JTWL-C20000 |

20 |

200 |

36 |

46 |

350 |

12 |

| JTWL-C30000 |

30 |

300 |

54 |

69 |

500 |

15 |

Project Case

Sodium hypochlorite Generator for Cote d’Ivoire

8tons/day 10-12%

Product detail pictures:

Related Product Guide:

Every single member from our large efficiency profits team values customers' requirements and organization communication for Good Quality Sodium Hypochlorite Generator - 8tons Sodium Hypochlorite Generator – Jietong Water Treatment , The product will supply to all over the world, such as: Argentina, Puerto Rico, Croatia, Insisting over the high-quality generation line management and prospects guide provider, we've made our resolution to offer our shoppers using the initially stage purchasing and soon after provider working experience. Preserving the prevailing helpful relations with our prospects, we even now innovate our product lists the many time to meet up with the brand new wants and stick to the latest trend of this business in Ahmedabad. We're ready to facial area the difficulties and make the transform to grasp many of the possibilities in international trade.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!