Manufacturer of Ro Water Filter System - High Pure Water Making Machine Brackish Water Purfication Filter – Jietong Water Treatment

Manufacturer of Ro Water Filter System - High Pure Water Making Machine Brackish Water Purfication Filter – Jietong Water Treatment Detail:

Explanation

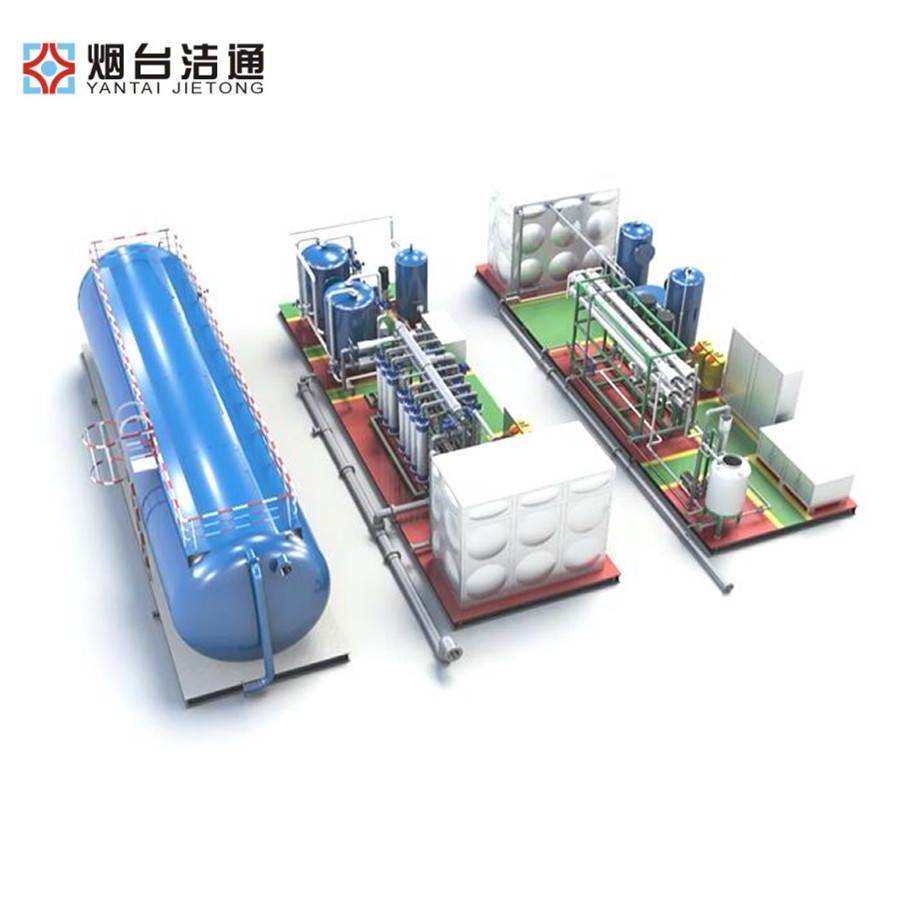

Pure water / high purity water treatment system is a kind of system to achieve the purpose of water purifying through various water treatment processes and water quality monitoring system. As per the users’ different requirements of the purity of the water, we combine and permute the pretreatment, reverse osmosis and mixed bed ion exchange (or EDI electric desalting unit) to make a set of pure water treatment equipment, moreover, all the water tanks in the system are equipped with liquid level control system, and the pumps are equipped with pressure protection device, on-line water quality detection and control instrument and PLC programmable controller are applied for the whole system to make the equipment running with no labor on duty.

Process Flow

Raw water tank → Raw water pump → Quartz sand filter → One stage security filter → UF systemð UF treated water tank → RO high pressure pump → RO water tank → Two stage high pressure pump → Two stage RO unit → RO water tankð Ion exchanger booster pump → Ion exchanger → Degasser unit → Water supply pump

Components

● RO membrane: DOW, Hydraunautics, GE

● Vessel: ROPV or First Line, FRP material

● HP pump: Danfoss super duplex steel

● Energy recovery unit: Danfoss super duplex steel or ERI

● Frame: carbon steel with epoxy primer paint, middle layer paint, and polyurethane surface finishing paint 250μm

● Pipe: Duplex steel pipe or stainless steel pipe and high pressure rubber pipe for high pressure side, UPVC pipe for low pressure side.

● Electrical: PLC of Siemens or ABB , electrical elements from Schneider.

Application

● Direct Flow High pressure Steam boiler (steam injection boiler) for Oilfield heavy oil recovery

● Brewery

● Power plant

● Pharmaceutical water

● Home Drinking water

● Industrial factory

● Public works

Reference Parameters

|

Model |

Capacity ( t/d ) |

Working Pressure (MPa) |

Inlet Water Temperature (℃) |

Recovery (%) |

|

JTRO-JS10 |

10 |

0.8-1.6 |

5-45 |

50 |

|

JTRO-JS25 |

25 |

0.8-1.6 |

5-45 |

50 |

|

JTRO-JS50 |

50 |

0.8-1.6 |

5-45 |

65 |

|

JTRO- JS 100 |

100 |

0.8-1.6 |

5-45 |

70 |

|

JTRO- JS 120 |

120 |

0.8-1.6 |

5-45 |

70 |

|

JTRO- JS 250 |

250 |

0.8-1.6 |

5-45 |

70 |

|

JTSO- JS 300 |

300 |

0.8-1.6 |

5-45 |

70 |

|

JTRO- JS 500 |

500 |

0.8-1.6 |

5-45 |

70 |

|

JTRO- JS 600 |

600 |

0.8-1.6 |

5-45 |

70 |

|

JTRO- JS 1000 |

1000 |

0.8-1.6 |

5-45 |

70 |

Project Case

High Pure Water Making machine

720tons/day for oil refinery plant

River water purification machine

for Industrial Factory

Product detail pictures:

Related Product Guide:

We constantly function like a tangible group to ensure that we can give you the very best high-quality and also the very best cost for Manufacturer of Ro Water Filter System - High Pure Water Making Machine Brackish Water Purfication Filter – Jietong Water Treatment , The product will supply to all over the world, such as: French, Southampton, Slovakia, Our products have enjoyed a great reputation for their good quality, competitive prices and prompt shipment in international market. Presently, we are sincerely looking forward to cooperating with more overseas customers based on mutual benefits.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.