PriceList for Sodium Hypochlorite Safety Generator - 5tons Sodium Hypochlorite Generator – Jietong Water Treatment

PriceList for Sodium Hypochlorite Safety Generator - 5tons Sodium Hypochlorite Generator – Jietong Water Treatment Detail:

Explanation

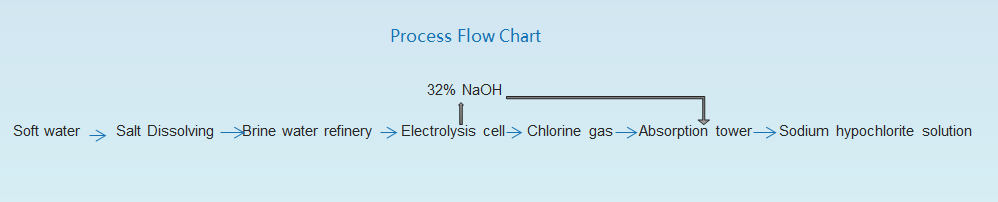

This is medium size sodium hypochlorite producing machine to produce 5-12% sodium hypochlorite bleaching solution.

Quick Details

Place of Origin:China Brand Name:JIETONG

Warranty:1 Year

Capacity: 5tons /day sodium hypochlorite generator

Characteristic: customerized Production time:90days

Certificate:ISO9001, ISO14001, OHSAS18001

Technical Data:

Capacity: 5tons/day

Concentration: 10-12%

Raw material: High Purity Salt and City tap water

Salt consumption: 1000kg/day

Power consumption: 88kw.h

Working Principle

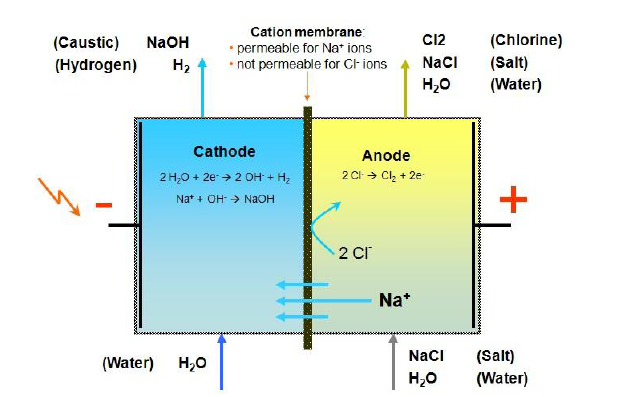

The basic principle of electrolytic reaction of membrane electrolysis cell is to convert electric energy into chemical energy and electrolyze brine to produce NaOH, Cl2 and H2 as shown in the above picture. In the anode chamber of the cell (on the right side of the picture), the brine is ionized into Na+ and Cl- in the cell, wherein Na+ migrates to the cathode chamber (left side of the picture) through a selective ionic membrane under the action of charge. The lower Cl- generates chlorine gas under anodic electrolysis. The H2O ionization in the cathode chamber becomes H+ and OH-, wherein OH- is blocked by a selective cation membrane in the cathode chamber and Na+ from the anode chamber is combined to form product NaOH, and H+ generates hydrogen under cathodic electrolysis.

Application

● Chlorine-alkali industry

● Disinfection for water plant

● Bleaching for clothes making plant

● Diluting to low concentration active chlorine for home, hotel, hospital.

Reference Parameters

|

Model

|

Chlorine (kg/h) |

NaClO (kg/h) |

Salt consumption (kg/h) |

DC Power consumption (kW.h) |

Occupy area (㎡) |

Weight (tons) |

| JTWL-C1000 |

1 |

10 |

1.8 |

2.3 |

5 |

0.8 |

| JTWL-C5000 |

5 |

50 |

9 |

11.5 |

100 |

5 |

| JTWL-C10000 |

10 |

100 |

18 |

23 |

200 |

8 |

| JTWL-C15000 |

15 |

150 |

27 |

34.5 |

200 |

10 |

| JTWL-C20000 |

20 |

200 |

36 |

46 |

350 |

12 |

| JTWL-C30000 |

30 |

300 |

54 |

69 |

500 |

15 |

Project Case

Sodium hypochlorite Generator for Somalia

5tons/day 12%

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for PriceList for Sodium Hypochlorite Safety Generator - 5tons Sodium Hypochlorite Generator – Jietong Water Treatment , The product will supply to all over the world, such as: Brunei, French, Bahamas, Our company promises: reasonable prices, short production time and satisfactory after-sales service, we also welcome you to visit our factory at any time you want. Wish we have a pleasant and long terms business together!!!

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!