Reasonable price Power Plant Seawater Electrolysis System - MGPS Seawater Electrolysis Online Chlorination System – Jietong Water Treatment

Reasonable price Power Plant Seawater Electrolysis System - MGPS Seawater Electrolysis Online Chlorination System – Jietong Water Treatment Detail:

Explanation

Seawater electrolysis chlorination system take use of natural seawater to produce on-line sodium hypochlorite solution with concentration 2000ppm by seawater electrolysis, which can effectively prevent the growth of organic matter on the equipment. The sodium hypochlorite solution is directly dosed to sea water through the metering pump, effectively control the growth of the sea water microorganisms, shellfish and other biological. and is widely used in the coastal industry. This system can meet the seawater sterilization treatment of less than 1 million tons per hour. The process reduces potential safety hazards related to the transportation, storage, transportation and disposal of chlorine gas.

This system has been widely used in large power plants, LNG receiving stations, seawater desalination plants, nuclear power plants, and seawater swimming pools.

Reaction Principle

First the seawater passes through the seawater filter, and then flow rate is adjusted to enter the electrolytic cell, and direct current is supplied to the cell. The following chemical reactions occur in the electrolytic cell:

Anode reaction:

Cl¯ → Cl2 + 2e

Cathode reaction:

2H2O + 2e → 2OH¯ + H2

Total reaction equation:

NaCl + H2O → NaClO + H2

The generated sodium hypochlorite solution enters the sodium hypochlorite solution storage tank. A hydrogen separation device is provided above the storage tank. The hydrogen gas is diluted below the explosion limit by an explosion-proof fan and is emptied. The sodium hypochlorite solution is dosed to the dosing point through the dosing pump to achieve sterilization.

Process flow

Seawater pump → Disc filter → Electrolytic cell → Sodium hypochlorite storage tank → Metering dosing pump

Application

● Seawater Desalination Plant

● Nuclear power station

● Sea Water Swimming Pool

● Vessel/Ship

● Coastal thermal power plant

● LNG Terminal

Reference Parameters

|

Model |

Chlorine (g/h) |

Active Chlorine Concentration (mg/L) |

Seawater flow rate (m³/h) |

Cooling water treatment capacity (m³/h) |

DC Power consumption (kWh/d) |

|

JTWL-S1000 |

1000 |

1000 |

1 |

1000 |

≤96 |

|

JTWL-S2000 |

2000 |

1000 |

2 |

2000 |

≤192 |

|

JTWL-S5000 |

5000 |

1000 |

5 |

5000 |

≤480 |

|

JTWL-S7000 |

7000 |

1000 |

7 |

7000 |

≤672 |

|

JTWL-S10000 |

10000 |

1000-2000 |

5-10 |

10000 |

≤960 |

|

JTWL-S15000 |

15000 |

1000-2000 |

7.5-15 |

15000 |

≤1440 |

|

JTWL-S50000 |

50000 |

1000-2000 |

25-50 |

50000 |

≤4800 |

|

JTWL-S100000 |

100000 |

1000-2000 |

50-100 |

100000 |

≤9600 |

Project Case

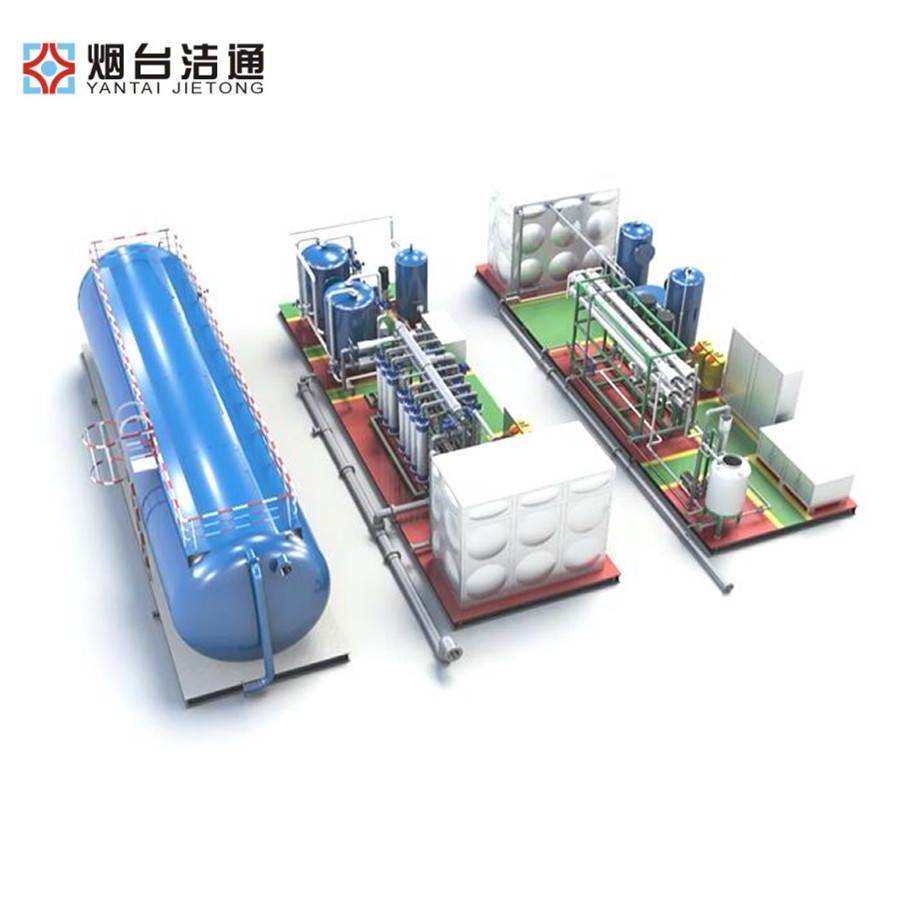

MGPS Seawater Electrolysis online Chlorination System

6kg/hr for Korea Aquarium

MGPS Seawater Electrolysis online Chlorination System

72kg/hr for Cuba power plant

Product detail pictures:

Related Product Guide:

Our pursuit and enterprise goal is to "Always satisfy our customer requirements". We keep on to establish and style and design outstanding top quality goods for both our outdated and new prospects and realize a win-win prospect for our clientele likewise as us for Reasonable price Power Plant Seawater Electrolysis System - MGPS Seawater Electrolysis Online Chlorination System – Jietong Water Treatment , The product will supply to all over the world, such as: Estonia, Las Vegas, Finland, We can meet the various needs of customers at home and abroad. We welcome new and old customers to come to consult & negotiate with us. Your satisfaction is our motivation! Let us work together to write a brilliant new chapter!

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.