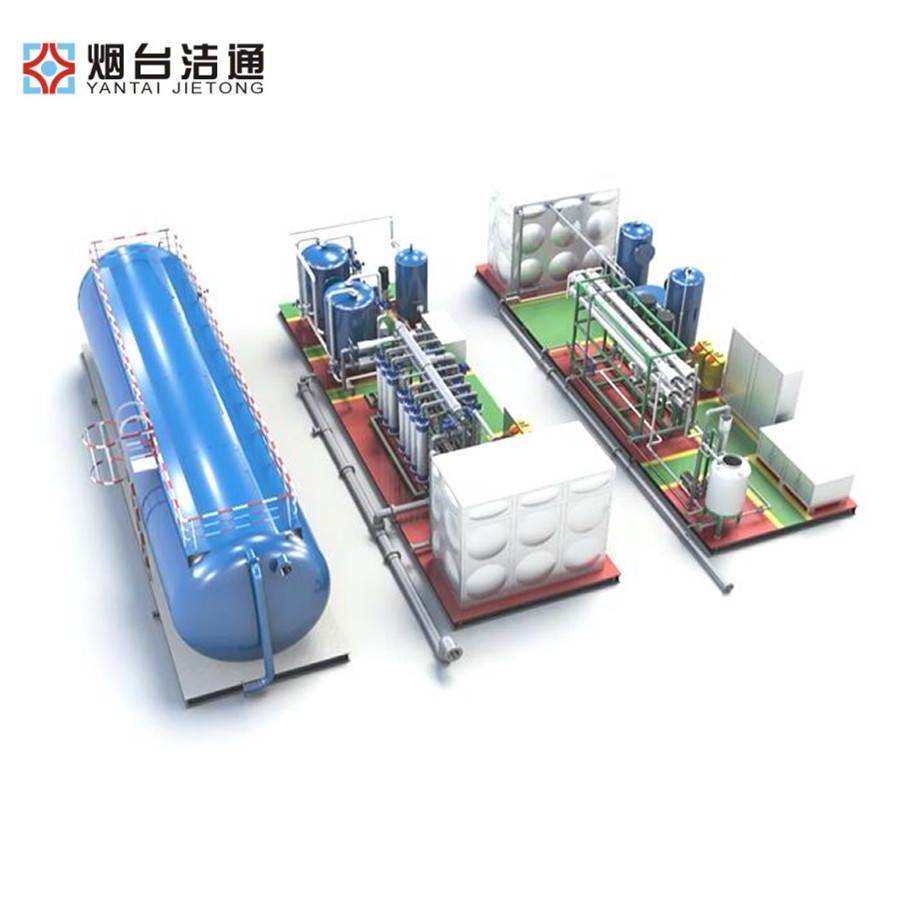

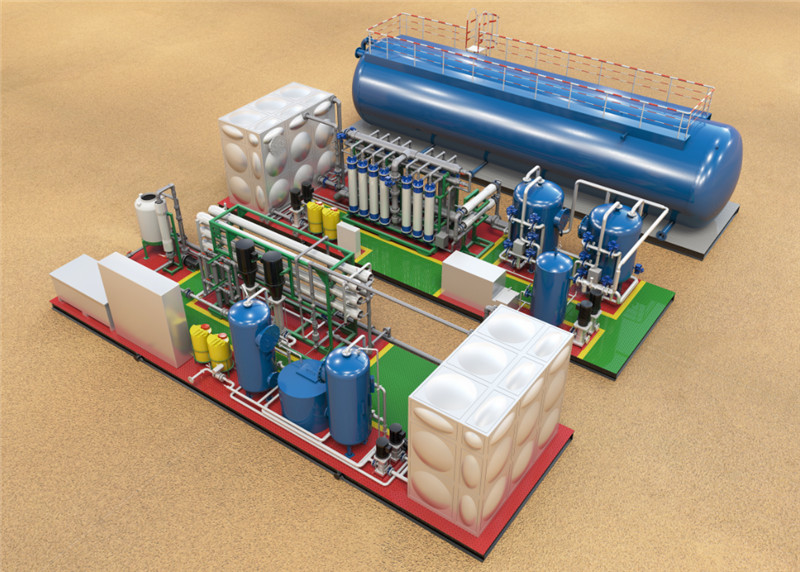

Steam Boiler Feeding Water Treatment System

Explanation

Pure water / high purity water treatment system is a kind of device to achieve the purpose of water purifying through various water treatment processes and water quality monitoring system. As per the users’ different requirements of the purity of the water, we combine and permute the pretreatment, reverse osmosis and mixed bed ion exchange (or EDI Electro-deionization) to make a set of tailored pure water treatment equipment, moreover, all the water tanks in the system are equipped with liquid level control system, and the pumps are equipped with pressure protection device, on-line water quality detection and control instrument and PLC programmable controller are applied for the whole system to make the equipment running with no labor onduty.

Quick Details

Place of Origin:China Brand Name:JIETONG

Warranty:1 Year

Characteristic: customerized Production time: 90days

Certificate:ISO9001, ISO14001, OHSAS18001

Process Flow

Seawater → Lifting pump → Flocculant sediment tank → Raw water booster pump → Quartz sand filter → Activated carbon filter → Security filter → Precision filter → High pressure pump → RO system → EDI system → Production water tank → water distribution pump

Components

● RO membrane: DOW, Hydraunautics, GE

● Vessel:ROPV or First Line, FRP material

● HP pump:Danfoss super duplex steel

● Energy recovery unit:Danfoss super duplex steel or ERI

● Frame:carbon steel with epoxy primer paint, middle layer paint, and polyurethane surface finishing paint 250μm

● Pipe:Duplex steel pipe or stainless steel pipe and high pressure rubber pipe for high pressure side, UPVC pipe for low pressure side.

● Electrical: PLC of Siemens or ABB , electrical elements from Schneider.

Application

● Marine engineering

● Power plant

● Oil field, petrochemical

● Processing enterprises

● Public energy units

● Industry

● Municipal city drinking water plant

Reference Parameters

|

Model |

Production water (t/d) |

Working Pressure (MPa) |

Inlet water temperature(℃) |

Recovery rate (%) |

Dimension (L×W×H(mm)) |

|

JTSWRO-10 |

10 |

4-6 |

5-45 |

30 |

1900×550×1900 |

|

JTSWRO-25 |

25 |

4-6 |

5-45 |

40 |

2000×750×1900 |

|

JTSWRO-50 |

50 |

4-6 |

5-45 |

40 |

3250×900×2100 |

|

JTSWRO-100 |

100 |

4-6 |

5-45 |

40 |

5000×1500×2200 |

|

JTSWRO-120 |

120 |

4-6 |

5-45 |

40 |

6000×1650×2200 |

|

JTSWRO-250 |

250 |

4-6 |

5-45 |

40 |

9500×1650×2700 |

|

JTSWRO-300 |

300 |

4-6 |

5-45 |

40 |

10000×1700×2700 |

|

JTSWRO-500 |

500 |

4-6 |

5-45 |

40 |

14000×1800×3000 |

|

JTSWRO-600 |

600 |

4-6 |

5-45 |

40 |

14000×2000×3500 |

|

JTSWRO-1000 |

1000 |

4-6 |

5-45 |

40 |

17000×2500×3500 |

Project Case

Seawater Desalination machine

720tons/day for offshore oil refinery plant

Container Type Seawater Desalination machine

500tons/day for Drill Rig Platform