Trending Products River Water Purification Equipment - Brine Electrolysis Online Chlorination System – Jietong Water Treatment

Trending Products River Water Purification Equipment - Brine Electrolysis Online Chlorination System – Jietong Water Treatment Detail:

Explanation

Take food grade salt and tap water as raw material through the electrolytic cell to prepare a 0.6-0.8% (6-8g/l)low concentration sodium hypochlorite solution on site. It replaces high-risk liquid chlorine and chlorine dioxide disinfection systems, and is widely used in large and medium-sized water plants. The safety and superiority of the system are recognized by more and more customers. The equipment can treat drinking water less than 1 million tons per hour. This process reduces potential safety hazards related to the transportation, storage, and disposal of chlorine gas. The system has been widely used in water plant disinfection, municipal sewage disinfection, food processing, oil field re-injection water, hospitals, power plant circulating cooling water sterilization, the safety, reliability, and economy of the entire system have been unanimously approved by users.

Reaction Principle

Anode side 2 Cl ̄ * Cl2 + 2e Chlorine evolution

Cathode side 2 H2O + 2e * H2 + 2OH ̄ hydrogen evolution reaction

chemical reaction Cl2 + H2O * HClO + H+ + Cl ̄

Total reaction NaCl + H2O * NaClO + H2

Sodium hypochlorite is one of the highly oxidizing species known as “active chlorine compounds” (also often referred to as “effective chlorine”). These compounds have chlorine-like properties but are relatively safe to handle. The term active chlorine refers to the released active chlorine, expressed as the amount of chlorine having the same oxidizing power.

Process flow

Pure water → Salt dissolving tank → Booster pump → Mixed salt box → Precision filter → Electrolytic cell → Sodium hypochlorite storage tank → Metering pump

Application

● Water plants disinfection

● Municipal sewage disinfection

● Food Processing

● Oilfield reinjection water disinfection

● Hospital

● Power plant circulating cooling water sterilization

Reference Parameters

|

Model

|

Chlorine (g/h) |

NaClO 0.6-0.8% (kg/h) |

Salt consumption (kg/h) |

DC Power consumption (kW.h) |

Dimension L×W×H (mm) |

Weight (kgs) |

|

JTWL-100 |

100 |

16.5 |

0.35 |

0.4 |

1500×1000×1500 | 300 |

|

JTWL-200 |

200 |

33 |

0.7 |

0.8 |

1500×1000×2000 | 500 |

|

JTWL-300 |

300 |

19.5 |

1.05 |

1.2 |

1500×1500×2000 | 600 |

|

JTWL-500 |

500 |

82.5 |

1.75 |

2 |

2000×1500×1500 | 800 |

|

JTWL-1000 |

1000 |

165 |

3.5 |

4 |

2500×1500×2000 | 1000 |

|

JTWL-2000 |

2000 |

330 |

7 |

8 |

3500×1500×2000 | 1200 |

|

JTWL-5000 |

5000 |

825 |

17.5 |

20 |

6000×2200×2200 | 3000 |

|

JTWL-6000 |

6000 |

990 |

21 |

24 |

6000×2200×2200 | 4000 |

|

JTWL-7000 |

7000 |

1155 |

24.5 |

28 |

6000×2200×2200 | 5000 |

|

JTWL-15000 |

15000 |

1650 |

35 |

40 |

12000×2200×2200 | 6000 |

Project Case

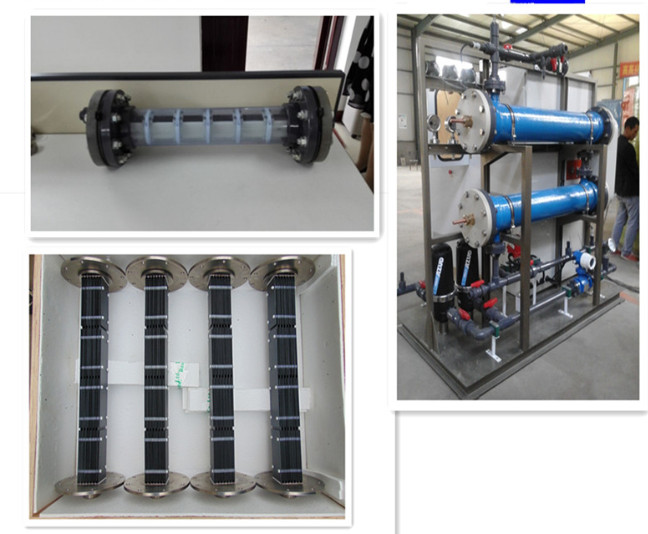

Brine Electrolysis online Chlorination System

5kg/hr 6-8g/l

Brine Electrolysis online Chlorination System

3.5kg/hr 6-8g/l

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product Quality, Reasonable Price and Efficient Service" for Trending Products River Water Purification Equipment - Brine Electrolysis Online Chlorination System – Jietong Water Treatment , The product will supply to all over the world, such as: Peru, Cannes, Singapore, With more than 9 years of experience and a professional team, we have exported our products to many countries and regions all over the world. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.